We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Conveyors

Industrial Conveyors from BHS, Inc. provide safe, efficient material handling along set travel paths. They help to automate material flow, reduce ergonomic hazards, and improve throughput for industrial facilities of all descriptions.

Our line of vertical conveyors includes Hydraulic Cantilever Vertical Reciprocating Conveyors (VRCs) and Mechanical Straddle VRCs. These are ideal for facilities with mezzanines, multiple stories, and multi-level production lines. We offer solutions for transporting everything from single parcels to full pallet loads, carts, and AGVs.

Vertical conveyors from BHS are designed for quick deployment and cost-effectiveness, delivering lower costs of ownership than freight elevators and fully custom builds. Hydraulic Cantilever VRCs ship fully assembled, and all models are remarkably quick and easy to install. They occupy compact footprints to avoid space challenges. Your choice of weight capacities, carriage size, and optional features ensures the right fit for your facility. Simply secure the unit, plug it in, and start lifting.

Contact the BHS Sales Team at 1.800.BHS.9500 to find a conveyor that fits seamlessly into your existing material handling system.

Vertical Conveyor Selection Guide

|

|

Load Type |

Carriage Platform Sizes |

Weight Capacities |

Max. Lifting Height |

Travel Speed |

Loading Pattern |

|

Hydraulic Cantilever VRC |

Pallet loads |

50” x 50” |

3,000 lb |

15 ft |

21 ft/min |

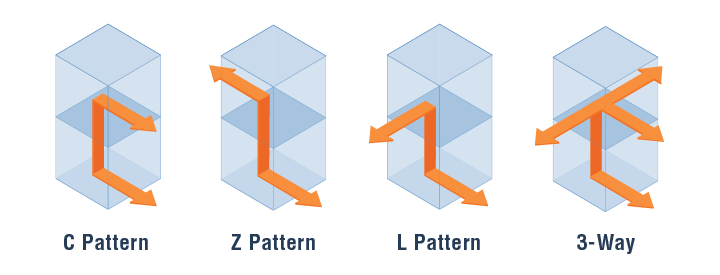

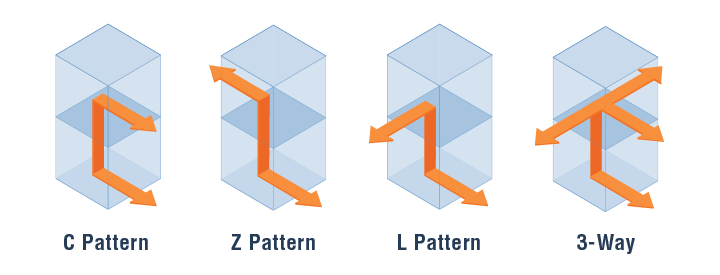

C, Z, L, 3-way |

|

Mechanical Straddle VRC |

Pallet loads |

50” x 50” |

3,000 lb |

25 ft |

28 ft/min |

C, Z |

VRC Loading Patterns

Compliance With Industrial Conveyor Standards and Regulations

All BHS conveyors comply with industry standards and safety regulations. For conveying equipment in the U.S., the key standards and regulations come from the Occupational Safety and Health Administration (OSHA) and the American Society of Mechanical Engineers (ASME).

Conveyors from BHS, Inc. comply with the following standards and regulations and more:

ASME B20.1 - Safety Standard for Conveyors and Related Equipment

This set of safety rules dictates technical specifications for engineering, building, installing, maintaining, and operating conveyors. Notably, this standard — and not an elevator standard — applies to Vertical Reciprocating Conveyors.

This distinction helps to drive down your total cost of ownership. The elevator standard — ASME 17.1/CSA B44: Safety Code for Elevators and Escalators — requires frequent and costly inspection and maintenance. Requirements for conveyors are less stringent.

That’s because Vertical Reciprocating Conveyors are limited to carrying materials, while elevators carry people. A VRC provides all the vertical lift power of a freight elevator without the extra costs. If you only need to move materials, and not personnel, a VRC will always be more cost-effective than an elevator.

OSHA 1926.555 - Conveyors

This OSHA standard for the construction industry refers conveyor users to ANSI B20.1. Standard 1926.555(a)(8) states that “all conveyors in use shall meet the applicable requirements for design, construction, inspection, testing, maintenance, and operation, as prescribed” in the ANSI standard, which is the same as the ASME standard listed above.

OSHA 1910.212 - Machinery and Machine Guarding

OSHA standard 1910.212 requires protective structures around hazardous parts of machinery, including conveyors. Every Vertical Reciprocating Conveyor fences off lift components and other moving parts.

OSHA 1910.28 - Duty to Have Fall Protection and Falling Object Protection

Vertical Reciprocating Conveyors don’t lift personnel, so there’s no requirement to include fall protection. But this OSHA standard also requires elevated platforms like VRCs to protect workers from falling objects — and this standard does apply to a VRC.

Specifically, standards 1910.28(c) and 1910.28(c)(1) state that “the employer must protect employees from falling objects by implementing one or more of the following: Erecting toeboards, screens, or guardrail systems to prevent objects from falling to a lower level.” Vertical Reciprocating Conveyors from BHS, Inc. feature fully enclosed carriages that meet this requirement. Gate and door sensors prevent operation until the carriage is fully enclosed, while velocity fuses and drop locks offer another layer of protection.

Learn more about Industrial Conveyors from BHS, Inc. by contacting our sales team at 1.800.BHS.9500.